Hanley Smith Ltd is supporting the Navy by manufacturing and supplying a set of cylinders for use refurbishing a vintage Swordfish.

The Bristol Pegasus is a British nine-cylinder; single-row, air-cooled radial aero engine originally built by the Bristol Aeroplane Company. The Pegasus engine was used to power both civil and military aircraft of the 1930s and 1940s. It was developed from the earlier Mercury and Jupiter engines and by the end of production over 30,000 Pegasus engines had been built.

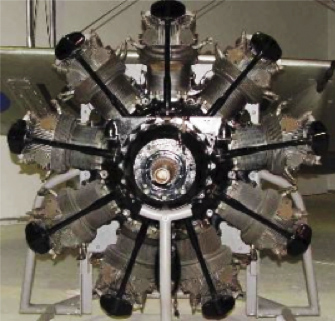

A Pegasus engine showing the nine radially mounted cylinders.

The cylinders were machined from solid, as casting them for low volume would not make economic sense. On each cylinder barrel there are 32 fins which are all different in form as well as the radial variations. To meet these parameters required very high quality and precision machining. Once the machining was completed heat treatments were applied and also Nitriding to full specifications.

(Nitriding is a heat treatment process that diffuses nitrogen into the surface of a metal to create a case hardened surface. It is predominantly used on steel.)

The cylinder heads were machined to add a sealing washer and finally put together with the cylinder barrel to make the complete assembly.